The ask

A Silicon Valley chip manufacturer was looking for a new way to identify and remove cracked silicon dies (small blocks of semiconductor material) from the production line in real time, without disrupting the manufacturing process.

Historically, these cracks were easy to spot using low grade vision systems. But as the requirement for smaller chips increased, die manufacturers have had to reduce wafer thickness via backgrinding. Backgrinding produces lines (a.k.a. scars) on the dies that make cracks harder to identify.

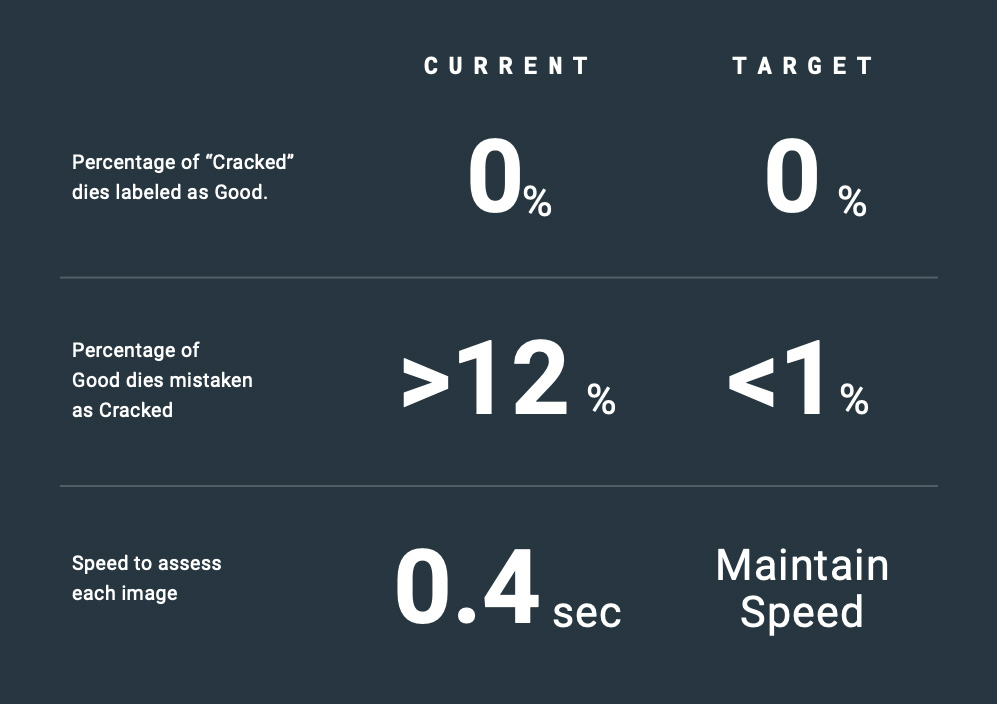

The manufacturer asked for our help in creating a new solution that could be embedded into their current production line and related systems, and that could meet three business acceptance criteria:

What we did

We created an A.I. image recognition solution that uses existing and

synthesized data to accurately classify dies as “GOOD” or “CRACKED”. The

solution then appropriately instructs the production line to continue or

remove each die.

Seamless integration with the client’s existing systems ensures this is

achieved while maintaining the third criteria: production speed.

Thanks to the use of Machine Learning, the solution is fully retrainable,

meaning its accuracy is continuously and remotely improved. This also

means it has the potential to be retrained for multiple different product

types.

A.I. IMAGE RECOGNITION IS ABLE TO ACCURATELY CLASSIFY DIES AS ”GOOD” OR ”CRACKED” WITHOUT IMPACTING PRODUCTION SPEED.

The process

There were three challenges facing quality assurance.

CHALLENGE 01

PROVIDING ACCURATE A.I. TRAINING DATA

The first challenge was a lack of data available to train the A.I. with,

which is a common issue for anomaly detection projects. In this case,

there were very few numbers of “CRACKED” die images to work with. We

used two data augmentation approaches to solve this. The first was to

split each cracked image into smaller windows, and then flip and rotate

them to provide 10x the amount of examples. We also used data

synthesization techniques to create hugely realistic replicas of cracked

dies using real world examples as a base. It was crucial in this stage to

ensure that the A.I. model was able to detect real-world cracks by using

information from the synthesised cracks – in other words, they needed to

be realistic enough to give an accurate reading. Once we had verified that

the models were accurate enough, we were able to combine these two

methods to give us a representative amount of information to train the

Machine Learning model, meaning we could accurately classify a wider

variance of images.

01

Original

02

Window Creation

03

10x Augmentation

CHALLENGE 02

DIFFERENTIATING CRACKS FROM SCARS

Our second challenge was to enable the A.I. solution to differentiate

cracks from backgrinding scars. Unlike cracks, the scars occur in

uniformed patterns due to the backgrinding process. Through careful

research and experimentation, our experienced Data Scientists were able

to identify the best scientific approach of using Fourier Transforms to

identify backgrinding stripe masks. We then applied these masks to the

images and then reversed the Fourier Transforms to provide cleaned

images. Since cracks are never uniform, this process ensured cracks

would not be removed from images by mistake.

01

Original

02

Masking scars

03

Cracks become visible

CHALLENGE 03

MEETING COMMERCIAL DEMANDS

The final challenge was to meet the production line requirements, allowing

the solution to work not just from a theoretical point of view, but to be

applicable in the real world where it can meet the commercial demands of

the business. To achieve this, we needed to take A.I. out of the lab and

into production by using our 20 years’ engineering and integration

experience and understanding of technical capabilities gained from

Intelygenz Labs. In this case, we needed to utilise the customer’s

centrally-controlled Edge computing abilities in order to meet the

operational needs and ensure commercial viability. To achieve this, we

used a cloud environment to simulate and fine tune the solution, with the

intention of porting it to local hardware once ready. This approach allows

us to flexibly make adjustments and ensures the final solution will meet

the speed requirements when applied in the real-world environment.

In the current simulated environment, this computer vision A.I. solution

automates the identification and diversion of faulty dies with an extremely

high level of accuracy. The solution has a false negative error rate of 0%,

meaning no faulty dies are classified as “GOOD”.

THE FINAL SOLUTION CLASSIFIES DIES WITH A FALSE NEGATIVE ERROR RATE OF 0% AND FALSE POSITIVE ERROR RATE OF < 1%.

We’ve also significantly reduced the false positive error rate that was

originally above 12% to below <1%, meaning very few non-faulty dies are

classified as “CRACKED”.

Current speed tests indicate images can be processed in less than 0.7

seconds, which we are able to improve by fine tuning and removing

complexities from the A.I. model. Once we achieve the business

acceptance criteria of less than 0.4 seconds while maintaining the same

false negative and false positive error rate, the solution will be placed into

full production.

Further improvements

Though we built this image recognition software for a specific product, its

A.I. model is continuously trainable. This means as more “GOOD” and

“CRACKED” dies are identified, the A.I. can continually learn from the data

and improve its accuracy over time. It also means the model can be

applied to any new products in the future, allowing the client to achieve

the same benefits of automation in manufacturing for other production

lines.

This solution can be applied to the quality assurance processes across

many industry verticals, as these same techniques can be trained to spot

imperfections in products on production lines throughout all stages of the

manufacturing process.